Plastic card printing technologies

A plastic card printer lets you customize plastic ID cards and badges for multiple uses: employee badges, loyalty cards, student cards, payment cards, among others.

The smooth surface and material of these plastic cards – generally in “credit card” format (5.4 x 8.6 cm) – require printing technologies different from those used in conventional paper printers (laser or inkjet). These systems use special processes to durably apply the ink needed for printing on plastic cards, thanks in large part to a ribbon. The ribbon is the equivalent of the ink cartridge in office paper printers.

The two printing processes used for plastic cards are:

Direct-to-card printing

This technology, also known as D2T2 (Dye Diffusion Thermal Transfer), combines monochrome thermal transfer processes and dye sublimation:

- Dye sublimation

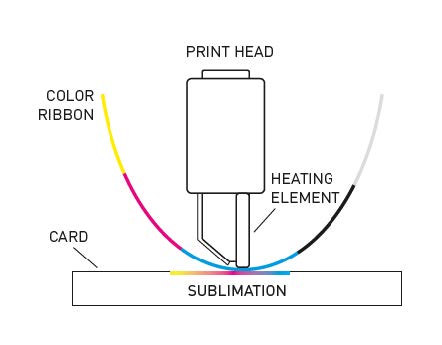

When using a ribbon consisting of color panels (yellow, magenta, cyan, and black), printing is carried out in several stages, with the print head heating each color panel one after the other. These layers of color then vaporize and solidify on the top layer of the plastic card. The layers are superimposed to achieve the required colors.

- Monochrome thermal transfer

Thermal transfer involves applying a single layer of color from a monochrome ribbon on the smooth, flat surface of the plastic card. This transfer is possible thanks to the print head, which, by increasing the temperature, heats up the areas to be printed on the colored layer of the ribbon before transferring it onto the card. A varnish is then applied to the card to maximize durability.

Retransfer printing

Retransfer technology (or reverse transfer) is a two-stage card printing process:

- The card design is printed in reverse on a transparent film. The process used is sublimation for the color (successive application of different layers of color) and thermal transfer for the black panel.

- The design printed on this film is then transferred onto the card, which reverses it again to achieve the correct orientation.

What are the benefits of these printing techniques?

The advantages of each of the two techniques are:

Direct-to-card printing:

- Good value for money

- Easy handling of a single print ribbon and simple management of consumables

- Option to customize pre-printed cards for variable elements (photos, text, barcodes)

- Faster print speed

Retransfer printing:

- Option to print on various card materials and on non-standard cards

- Card edges perfectly printed

- Improved card durability

- Print head preservation

In the Evolis range, the Avansia card printer offers this technology.

Advanced customization features

Plastic card printers can also use other technologies for more advanced card customization options. These technologies include features such as:

- Data encoding on contact and contactless chips or magnetic stripes

- Card lamination, with or without holograms (Evolis Primacy Lamination)

- Embossing (Evolis Privelio XT)

The options for printing and customizing your cards are vast and varied. By clearly defining your needs, you’ll be able to choose the ideal card printer and use the most appropriate technology for your project.